Industrial

Liquid Volume Measurement

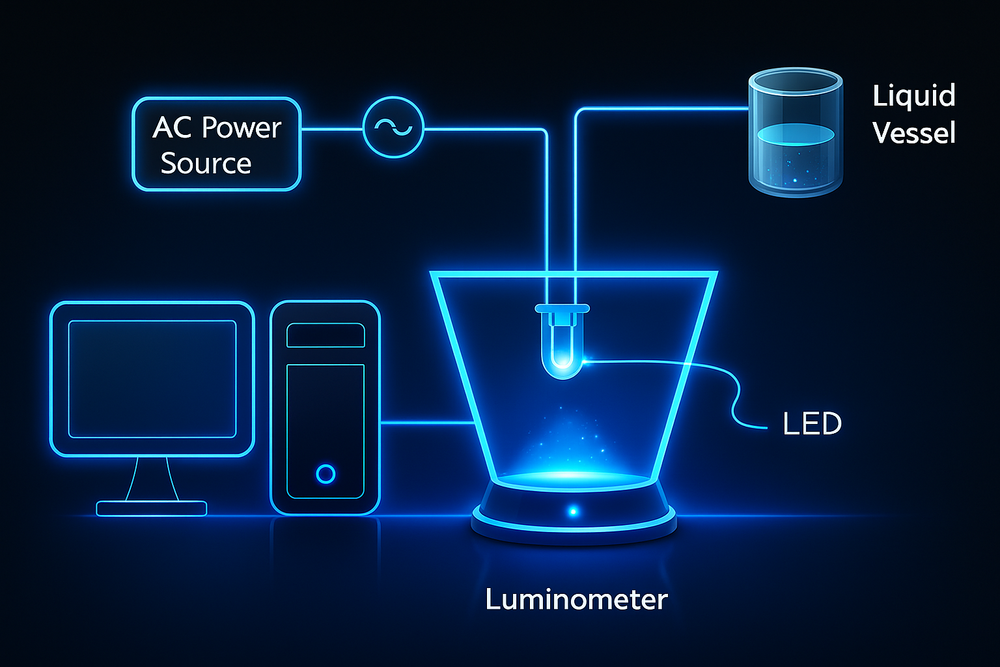

Accurate measurement of small liquid quantities—especially at the microliter scale and below—poses a significant challenge. Using the OCEL platform, the volume of liquid in contact with the EL-active component influences the degree to which electromagnetic waves are absorbed. This energy transfer causes the EL compound to emit light, with larger volumes resulting in stronger light emission. Employing ultra-sensitive light-emitting diodes in the OCEL platform, AhuraTech has achieved up to 99.99% accuracy in measuring nanoliter-scale volumes. By leveraging open-circuit electroluminescence to translate electromagnetic field variation directly into light-based optical readings, OCEL eliminates reliance on traditional active measurement circuits. OCEL thus enables highly stable detection across a wide dynamic range. Its low-cost implementation, combined with its inherent noise immunity, offers an attractive alternative to conventional electrical or optical measurement technologies. This modality can identify even minor variations in liquid geometry within sealed systems, minimizing operational risk while maintaining sub-nanoliter fidelity. The OCEL platform significantly enhances the precision of industrial liquid monitoring, enabling fluid-level fidelity and rapid detection of micro-scale volume changes in volume or composition—an innovation that redefines liquid metrology at the smallest measurable scale.

Polarity Detection

Fingerprint Visualization